Airplanes

We have now set the stage for the ultimate aerodynamic machines—airplanes. Freed from contact with the ground, airplanes are affected only by aerodynamic forces and gravity, hopefully in that order.

Airplane Wings: Streamlining

an airplane is supported in flight by an upward lift force on its wings and that this lift force comes from deflecting the passing airflow downward. Each wing is an airfoil, an aerodynamically engineered surface that’s designed to obtain particular lift and drag forces from the air flowing past it. More specifically, each wing is shaped and oriented so that, during flight, the airstream flowing over the wing bends downward toward its top surface while the airstream under the wing bends downward away from its bottom surface. These bends are associated with pressure changes near the wing itself and are responsible for the upward lift force that suspends the airplane in the sky.

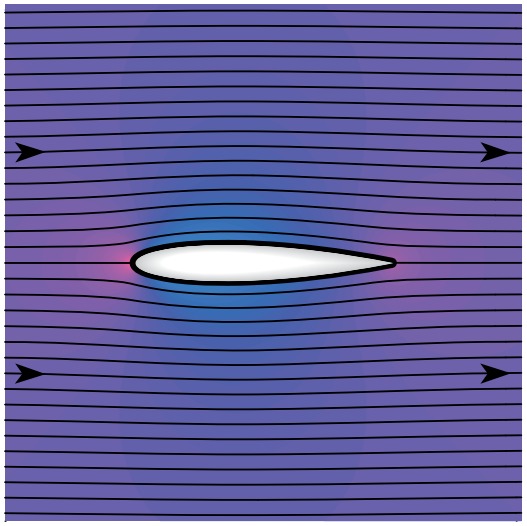

Imagine yourself in an airplane that has just begun rolling down the runway. From your perspective, air is beginning to flow past each of the airplane’s wings. When this moving air encounters the wing’s leading edge, it separates into two airstreams: one traveling over the wing and the other under it (Fig.). These airstreams continue onward until they leave the wing’s trailing edge. Since the airplane’s nose is still on the ground, the wing is essentially horizontal and the airflow around it is simple and symmetrical. Since the wing isn’t deflecting the airflow yet, it’s experiencing no lift, only drag. However, while this drag pushes the airplane downwind, opposite its forward motion along the runway, the effect is weak. The wing produces almost no turbulent wake and thus experiences almost no pressure drag. What little drag it does experience is mostly viscous drag, essentially surface friction with the passing air.

Although the wing’s near lack of air resistance should surprise you, you probably take it for granted. That’s because you’ve often observed that such “streamlined” objects cut through the air particularly well. Having a long, tapered tail allows the wing to avoid the flow separation and turbulent wake that occur behind an unstreamlined ball. What makes the horizontal wing streamlined is the extremely gradual rise in air pressure after its widest point. Although this gently rising pressure pushes the wing’s boundary layer backward, opposite the direction of flow, the force it exerts is so weak that the layer doesn’t stall. Driven onward by viscous forces from the freely flowing airstream, the wing’s boundary layer manages to keep moving forward all the way to the wing’s trailing edge and never triggers flow separation. The wing produces almost no turbulent wake and experiences almost no pressure drag.

Airplane Wings: Producing Lift

With so little air resistance, the airplane accelerates forward rapidly and soon reaches takeoff speed. The pilot then raises the airplane’s nose so that its wings are no longer horizontal, and they begin to experience upward lift forces. The airplane’s total lift soon exceeds its weight, and it begins to accelerate upward into the air. The airplane is flying!

Let’s take a closer look at the moment of takeoff. If you could see the airflow and were paying close attention, you’d notice a remarkable sequence of events that begins when the wings tilt upward.

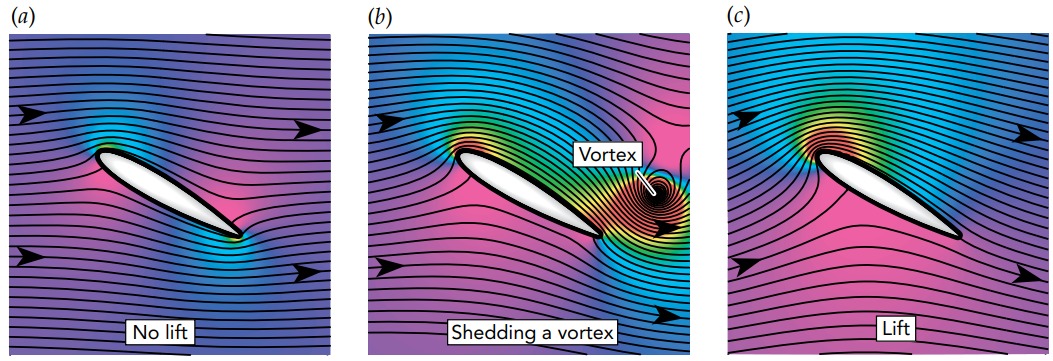

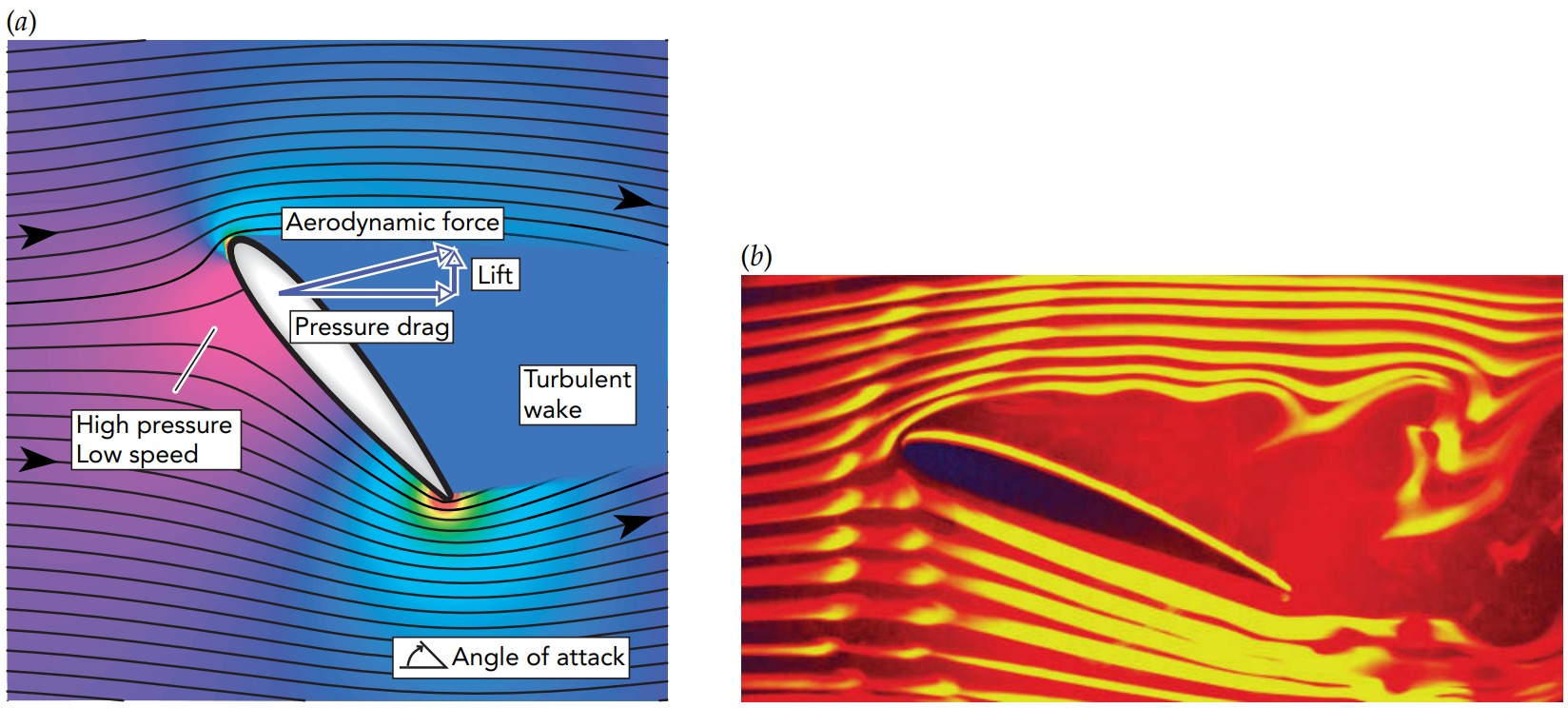

At first, the airflow around the tilted wings continues to travel horizontally on average, although it develops a peculiar shape (Fig.). The two airstreams, one over the tilted wing and one under it, each bend twice—once up and once down. As we saw while studying balls, when an airstream bends toward the wing, the pressure near the wing is less than atmospheric and when an airstream bends away from the wing, the pressure near the wing is greater than atmospheric. Since each airstream bends equally toward and away from the wing, the average pressures above and below the wing are equal and the wing experiences no lift. The lower airstream, however, is making a sharp bend around the wing’s trailing edge, essentially an upward kink. Air’s inertia makes such a kink unstable, and it soon blows away from the wing’s trailing edge as a swirling horizontal vortex of air (Fig.). After shedding that vortex, the wing establishes a new, stable flow pattern in which both airstreams glide smoothly away from the wing’s trailing edge (Fig.), a situation named the Kutta condition after the German mathematician M. Wilhelm Kutta (1867–1944).

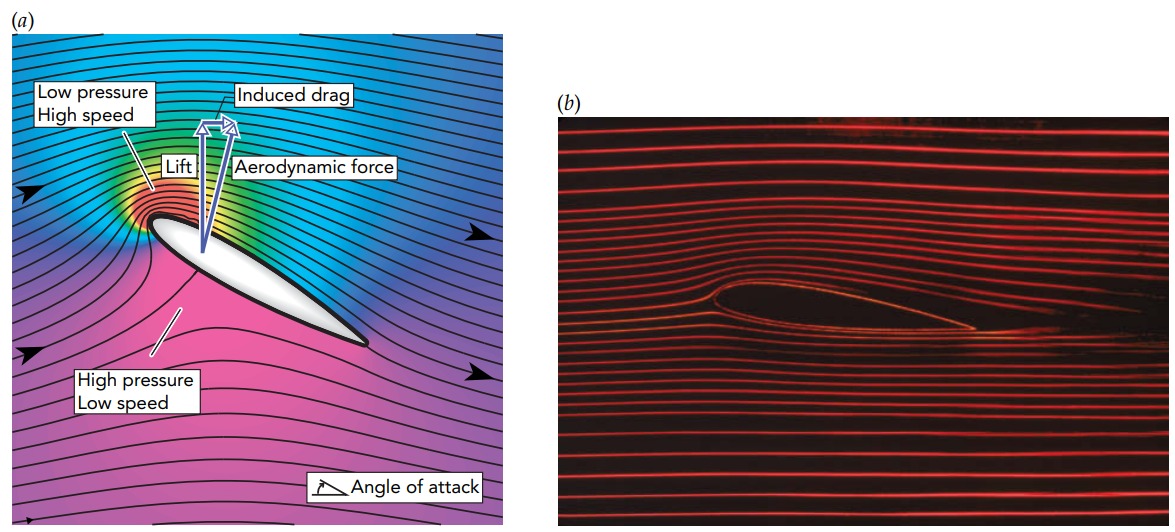

In this new pattern, the airstream flowing over the wing is longer than the airstream flowing under it and both airstreams bend downward (Fig.). The upper airstream bends primarily toward the wing, so the air’s pressure just above the wing is less than atmos pheric (a shift toward red) and its speed is increased (narrowly spaced streamlines). In contrast, the lower airstream bends primarily away from the wing, so the air’s pressure just below the wing is greater than atmospheric (a shift toward violet) and its speed is decreased (widely spaced streamlines). The air pressure is now higher under the wing than over it, so this new flow pattern produces upward lift. The air now supports your plane and up you go. Another way to think about this lift is as a deflection of the airflow. Air approaches the wing horizontally but leaves heading somewhat downward. To cause this deflection, the wing must push the airflow downward. In reaction, the airflow pushes the wing upward and produces lift. In other words, the wing transfers downward momentum to the air and is left with upward momentum. These two explanations for lift—the Bernoullian view that lift is caused by a pressure difference above and below the wing, and the Newtonian view that lift is caused by a transfer of momentum to the air—are perfectly equivalent and equally valid.

However, the overall aerodynamic force on the wing isn’t quite perpendicular to the onrushing air; it tilts slightly downwind. The perpendicular component of this aerodynamic force is lift, but the downwind component is a new type of drag force—induced drag. Induced drag is a consequence of energy conservation; in addition to transferring momentum to the passing air, the wing also transfers some energy to it. The air extracts that energy from the wing by pushing the wing downwind with induced drag and thereby doing negative work on it. Since induced drag is undesirable, the airplane minimizes it by using as much air mass as possible to obtain its lift. A larger mass of air carries away the airplane’s unwanted downward momentum while moving downward less quickly and with less kinetic energy. Since larger wings obtain their lift from larger air masses, they experience less induced drag.

Unfortunately, larger wings also have more surface area and experience more viscous drag, so bigger isn’t always better. Also, because wing shape and airspeed affect aerodynamic forces, too, wings must be carefully matched to their airplanes. Small propeller airplanes that move slowly through the air need relatively large, highly curved wings to support them. Those wings are often asymmetrical—more curved on top than on bottom to make maximum use of the limited, low-speed air they encounter each second. Commercial and military jets fly faster and encounter far more high-speed air each second, so they can get by with relatively small, moderately curved wings.

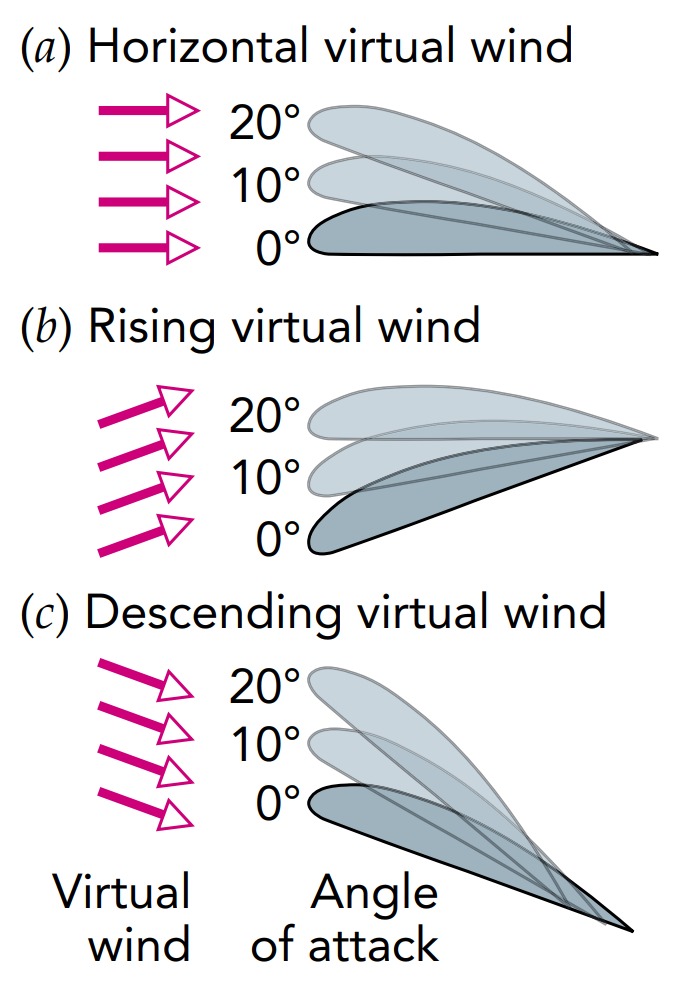

Even at constant airspeed, a wing’s lift can be adjusted by varying its angle of attack, the angle at which it approaches the onrushing air. The larger the angle of attack, the more the two airstreams bend and the greater the wing’s lift. Because the wings are rigidly attached to the plane, the pilot has no choice but to tip the entire plane to adjust its lift. The pilot tips the nose of the plane upward to increase the lift and downward to reduce the lift. That’s why raising the plane’s nose during takeoff is what finally makes the plane leap up into the air. Since lift depends so strongly on a wing’s angle of attack, some planes can be flown upside down. As long as the inverted wing is tilted properly, it obtains upward lift and supports the plane. This feat is easiest when a plane’s wing has the same curvature, top and bottom. That’s why stunt fliers who regularly fly upside down often use sport aircraft that have symmetrical or nearly symmetrical wings.

When a plane is in level flight through calm air, the wing’s angle of attack is simply its angle above horizontal (Fig.). As viewed from the plane’s inertial frame of reference, the air’s velocity is directed horizontally toward the plane and acts as a horizontal virtual wind as it approaches the wings. The angle of attack is measured relative to that virtual wind. When the plane is not in level flight or when the air itself is moving up or down, however, the virtual wind is no longer horizontal. While descending or flying through rising air, the plane encounters a rising virtual wind—the onrushing air’s velocity is tilted upward (Fig.). The wing’s angle of attack, still measured relative to that virtual wind, is greater than its angle above horizontal and its lift increases. While ascending or flying through descending air, the plane encounters a descending virtual wind—the onrushing air’s velocity is tilted downward (Fig.). The wing’s angle of attack is less than its angle above horizontal and its lift decreases. When a plane flies through bad weather, with air that is moving alternately up and down, the rapid changes in virtual wind direction lead to fluctuations in lift and exciting accelerations. No wonder there are air sickness bags in the seat pockets.

Lift Has Its Limits: Stalling a Wing

There’s a limit to how much lift the pilot can obtain by increasing the wing’s angle of attack because tilting the wing gradually transforms it from streamlined to blunt—that is, to having a rapid rise in air pressure after its widest point. As we saw for balls, blunt objects generally experience airflow separation and pressure drag. Indeed, beyond a certain angle of attack, the airstream over the top of a wing separates from its surface and the wing stalls. This separation starts when air in the upper boundary layer is brought to a standstill by the rapidly rising pressure beyond the wing’s widest point. Once this boundary layer stalls, it shaves most of the airstream away from the wing’s upper surface. The separated airstream over the top of the stalled wing leaves a billowing storm of turbulence beneath it (Fig.). This airstream separation is an aerodynamic catastrophe for the airplane. Because the average pressure above the wing increases, the wing loses much of its lift. Also, the appearance of a turbulent wake heralds the arrival of severe pressure drag. The plane slows dramatically and begins to fall. To avoid stalling, pilots keep the angle of attack within a safe range. The possibility of stalling also limits the minimum speed at which the airplane will fly. As the airplane slows down, the pilot must increase its angle of attack to maintain adequate lift. Below a certain speed, the airplane can’t obtain that lift without tilting its wings until they stall. It can no longer fly.

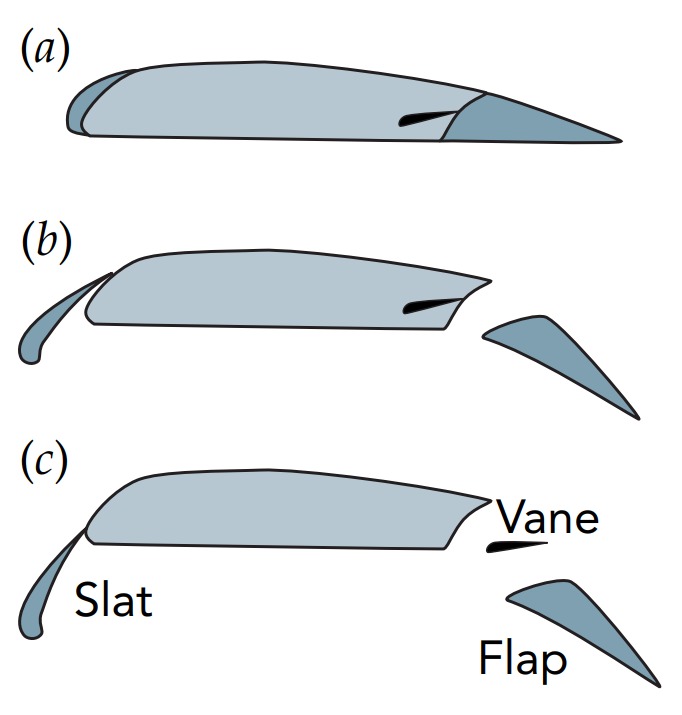

To avoid stalling, a plane must never fly slower than this minimum speed, particularly during landings and takeoffs. For a small, propeller-driven plane with highly curved wings, the minimum flight speed is so low that it’s rarely an issue. For a commercial jet, however, the minimum airspeed is about 220 km/h (140 mph). Airplanes taking off or landing this fast would require very long runways on which to build up or get rid of speed. Instead, commercial jets have wings that can change shape during flight. Slats move forward and down from the leading edges of the wings, and flaps move back and down from the trailing edges (Fig.). With both slats and flaps extended, the wing becomes larger and more curved, similar to the wings of a small propeller plane, and the minimum safe airspeed drops to a reasonable 150 km/h (95 mph). Vanes near the flaps also emerge during landings to direct high-energy air from beneath the wings onto the flaps. These jets of air keep the boundary layers moving downstream and help prevent stalling.

Once a commercial jet lands, flat panels on the top surfaces of its wings are tilted upward and cause the airflow to separate from the tops of the wings. The resulting turbulence created by these spoilers reduces the lift of the wings and increases their drag so the plane doesn’t accidentally start flying again. Even before landing, the spoilers are sometimes used to slow the plane and help it descend rapidly toward an airport. In flight, a wing does more than just push the passing air downward; it also twists the air near its tip. Since the air pressure below the wing is greater than the air pressure above it, air tends to flow around the wing’s tip from bottom to top. The plane soon leaves this air behind, but not before the air has acquired lots of angular momentum and kinetic energy.

A swirling vortex thus emerges from each wingtip and trails behind the plane for several kilometers, like an invisible tornado. You can occasionally see them behind a plane that’s landing or taking off in humid air. A wingtip vortex from a jumbo jet can flip over a small aircraft that flies through it or give passengers in a much larger plane an unexpected thrill. Entered from behind, one of these vortices feels like a horizontal blender; from the side, it feels like a speed hump that you might drive over in a car. For safety, air traffic controllers are careful to keep planes from flying through one another’s wakes and schedule them at least 90 seconds apart on runways. Many modern airplanes have vertical wingtip extensions that reduce these vortices, both to save energy and to diminish the hazard (Fig.).

Propellers

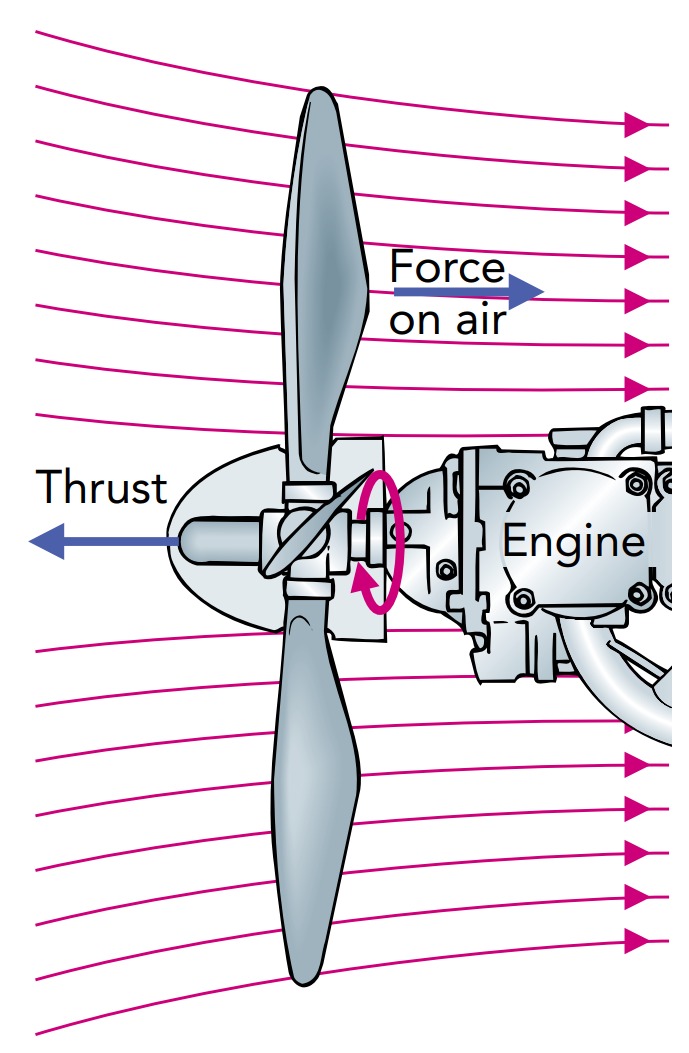

For a plane to obtain lift, it needs airspeed; air must flow across its wings. And since drag forces push it downwind, a plane in level flight can’t maintain its airspeed unless something pushes it upwind. That’s why a plane has propellers or jet engines, to push the air backward so that the air pushes the plane forward—action and reaction. A propeller is an assembly of rotating wings. Extending from its central hub are two or more blades that together form a sophisticated fan (Fig.). These blades have airfoil cross sections and are designed to create forward lift forces when the propeller turns and the blades move through the air.

As a propeller blade slices through the air, the airstreams bending around that blade experience pressure variations (Fig.). The forward airstream bends toward the blade’s front surface, so the pressure in front of the blade drops below atmospheric. The rearward airstream bends away from the blade’s rear surface, so the pressure behind the blade rises above atmospheric. The resulting pressure difference produces a forward force on the blade and propeller, a thrust force. The propeller blades have all the features, good and bad, of airplane wings. Their thrust increases with size, front-surface curvature, pitch (that is, angle of attack), and airspeed; in other words, the larger the propeller, the faster it turns, and the more its blades are angled into the wind, the more thrust it produces. The blades themselves have a twisted shape to accommodate the variations in airspeed along their lengths, from hub to tip.

Like a wing, a propeller stalls when the airflow separates from the front surfaces of its blades; it suddenly becomes more of an air mixer than a propeller. This stalled-wing behavior was the standard operating condition for air and marine propellers before the work of Wilbur Wright in 1902. One of the principal sources of noise in submarines is the turbulence created by their propellers. To reduce this turbulence, the propellers of modern nuclear submarines are designed to avoid water flow separation and stalling.

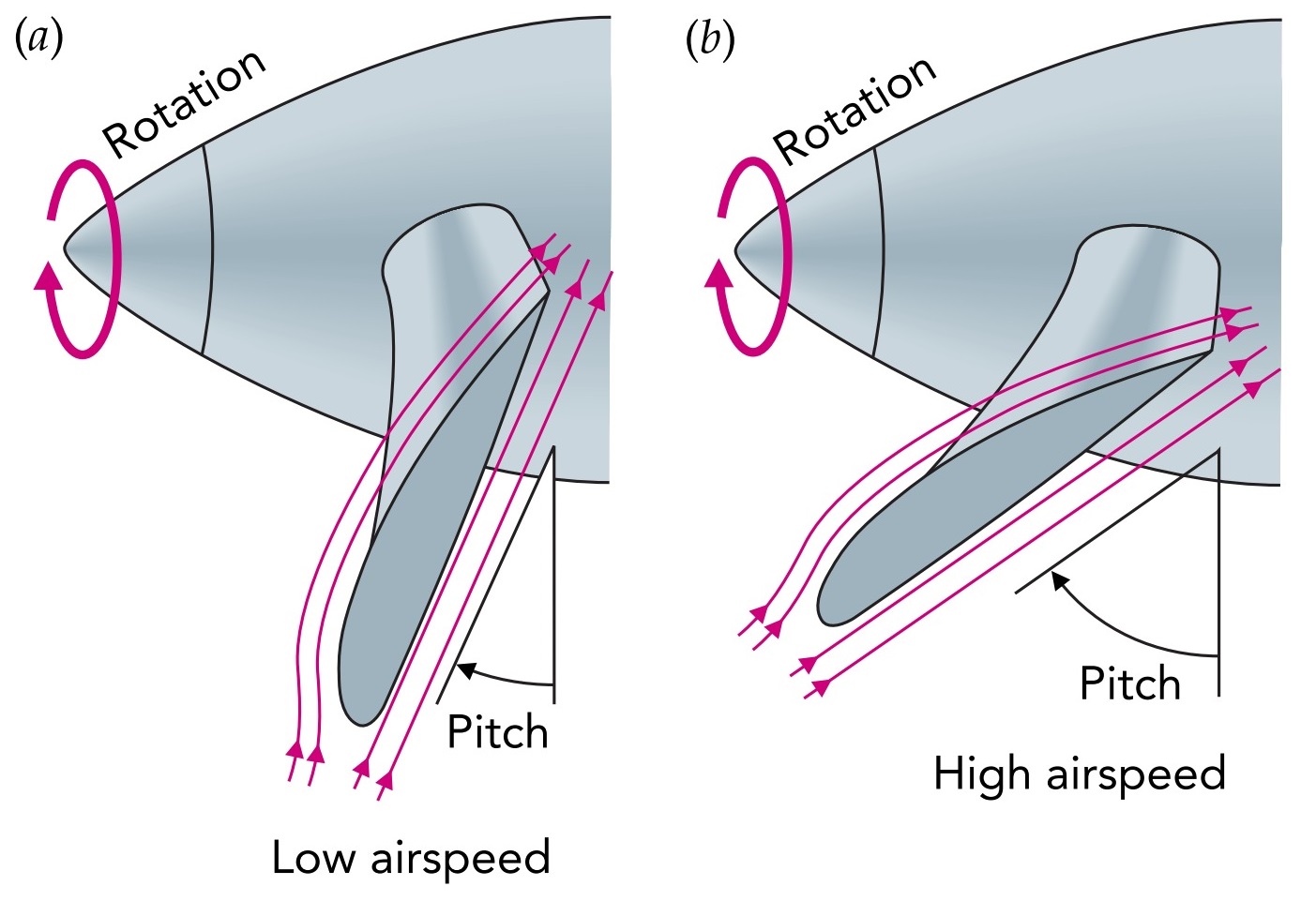

The Wrights were among the first people to study aerodynamics using a wind tunnel (Fig.), and their methodical and scientific approach to aeronautics allowed them to achieve the first powered flight (Fig.). Since the Wrights’ work, propellers have experienced almost no pressure drag. A propeller does, however, experience induced drag. As the propeller’s thrust pushes the plane through the air, induced drag extracts energy from the propeller. To keep the propeller turning steadily, an engine must do work on the propeller. Propellers are driven by high-performance reciprocating (piston-based) engines, like those found in automobiles, or by the turbojet engines that we’ll discuss later. Propellers aren’t perfect; they have three serious limitations. First, a propeller exerts a torque on the passing air, so that air exerts a torque on the propeller. This reaction torque can flip a small plane. To minimize torque problems, some planes use pairs of oppositely turning propellers and single-propeller planes usually locate their propellers in front so that the spinning air can return angular momentum to them while passing over their wings. A second problem with a propeller is that its thrust diminishes as the plane’s forward speed increases. When the airplane is stationary, a propeller blade moves through motionless air (Fig.). When the airplane is traveling fast, though, the air approaches that same propeller blade from the front of the plane (Fig.). To retain its thrust at higher airspeeds, the propeller blade must increase its pitch—that is, its angle of attack. It must swivel forward to meet the onrushing air.

The third and most discouraging problem with propellers, especially in high-speed aircraft, is drag. To keep up with the onrushing air at high airspeeds, the propellers must turn at phenomenal rates. The tips of the blades must travel so fast that they exceed the speed of sound, the fastest speed at which a fluid such as air can convey forces from one place to another. When the blade tip exceeds this speed, the air near the tip doesn’t accelerate until the tip actually hits it. Instead of flowing smoothly around the tip, the air forms a shock wave, a narrow region of high pressure and temperature caused by the supersonic impact, and the propeller stalls. That’s why propellers aren’t useful on high-speed aircraft.

Jet Engines

Unlike propellers, jet engines work well at high speeds. While a propeller tries to operate directly in the high-speed air approaching the plane, a jet engine first slows this air down to a manageable speed. To achieve this change in speeds, the jet engine makes wonderful use of the energy transformations allowed by Bernoulli’s equation. Strictly speaking, Bernoulli’s equation applies only to incompressible fluids such as water. Nonetheless, it’s often usable for compressible fluids such as air, especially when the speed and pressure variations are relatively small.

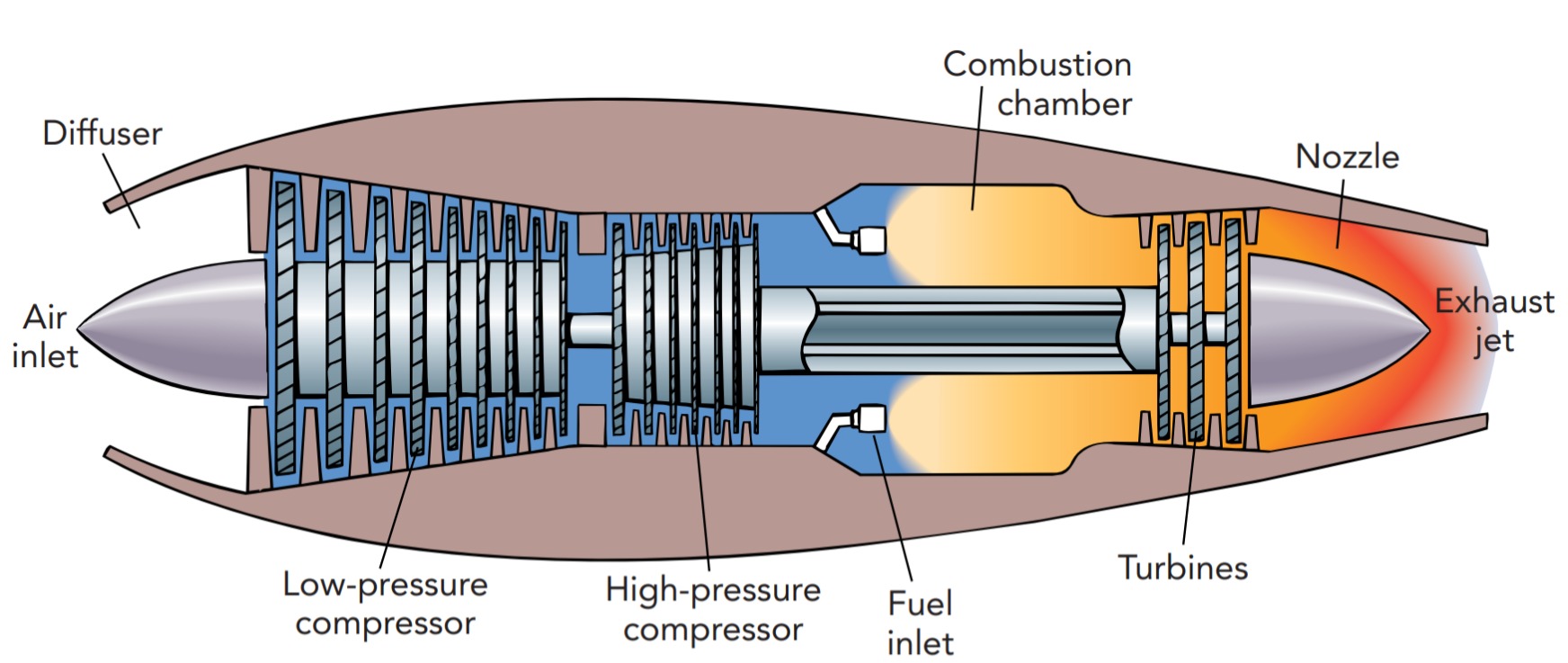

A turbojet engine is depicted in Fig. During flight, air rushes into the engine’s inlet duct or diffuser at about 800 km/h (500 mph), the airspeed of the plane. Once inside that diffuser, the air slows down and its pressure increases, leaving its ordered energy unchanged. The air then passes through a series of fanlike compressor blades that push it deeper into the engine, doing work on it and increasing both its pressure and its ordered energy. By the time the air arrives at the combustion chamber, its pressure is many times atmospheric.

Now fuel is added to the air, and the mixture is ignited. The pressure of this gaseous mixture doesn’t increase as it burns; instead, it expands to occupy more volume. Furthermore, combustion subdivides the fuel molecules into smaller pieces that, therefore, take up still more volume. This extremely hot, high-pressure exhaust gas pours out of the combustion chamber through a wider channel than the one it entered. The exhaust gas then streams through windmill-like turbine, doing work on that turbine and thereby powering the compressor for the incoming air. After the turbine, the still high-pressure gas finally accelerates and expands through the engine’s outlet nozzle and emerges into the open sky at atmospheric pressure, moderately high temperature, and extraordinarily high speed.

Overall, the engine slows the air down, adds energy to it, and then lets it accelerate back to high speed. Because the engine has added energy to the air, the air leaves the engine traveling faster than when it arrived. The air’s increased backward velocity means that the jet engine has pushed it backward and the air has reacted by exerting a forward thrust force on the jet engine. In other words, the airplane has obtained forward momentum by giving the departing air backward momentum. The turbojet is less energy efficient than it could be. Since it gives backward momentum to a relatively small mass of air, that air ends up traveling overly fast and with excessive kinetic energy. To make the engine more efficient, it should give backward momentum to a larger mass of air.

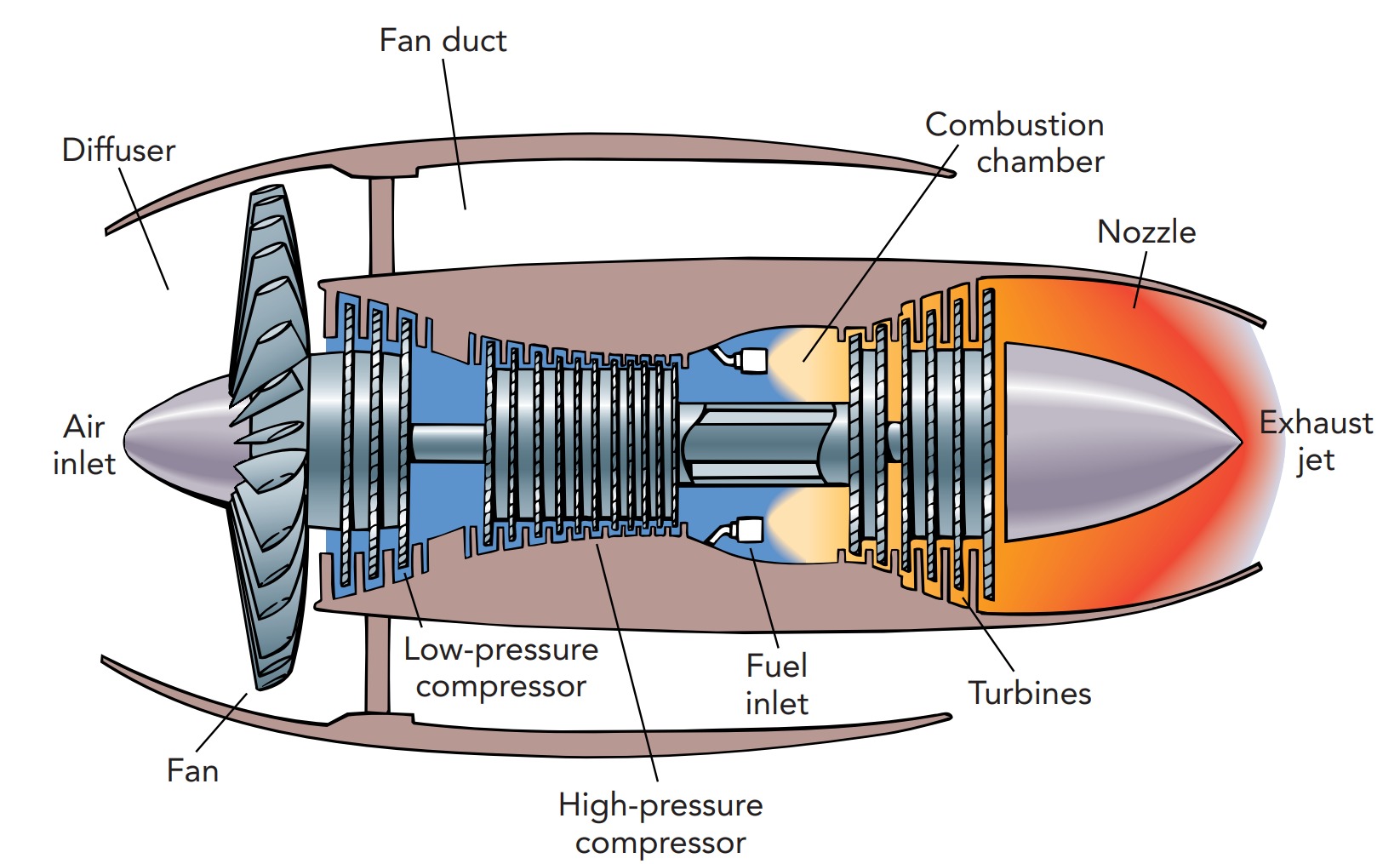

The turbofan engine solves this problem by using a turbojet engine to spin a huge fan (Fig.). Since this fan is located in the engine’s inlet duct, the air’s speed decreases and its pressure increases before it enters the fan. The fan then does work on the air and further increases its pressure. While about 5% of this air then enters the turbojet engine, the vast majority of it accelerates out the back of the fan duct and emerges into the open sky at atmospheric pressure and increased speed. Overall, the fan has pushed the air backward and the air has pushed the fan forward, producing forward thrust. Like a turbojet, the turbofan slows air down, adds energy to it, and then lets it accelerate back to high speed. However, because the turbofan engine moves more air than a turbojet engine, it gives that air less energy and uses less fuel. Because of their increased efficiency, turbofans are used in all modern commercial jets.

Ramjets

Ramjets are jet engines that have no moving parts. Air that approaches the engine at supersonic speeds interacts with carefully tapered surfaces so that its own forward momentum compresses it to high density. The engine then adds fuel to this pressurized air, ignites the mixture, and allows the hot burned gas to expand out of a nozzle. The engine pushes this exhaust backward, and the exhaust propels the engine and airplane forward. Although the air enters the engine at supersonic speeds, it passes through the combustion chamber much more slowly. In a supersonic combustion ramjet, or “scramjet,” the fuel and air mixture flows through the combustion chamber at supersonic speeds. This motion makes it extremely difficult to keep the fuel burning because the flame tends to flow downstream and out of the engine. The flame can’t advance through the mixture faster than the speed of sound, so it won’t spread upstream fast enough to stay in the engine on its own.