Xerographic Copiers

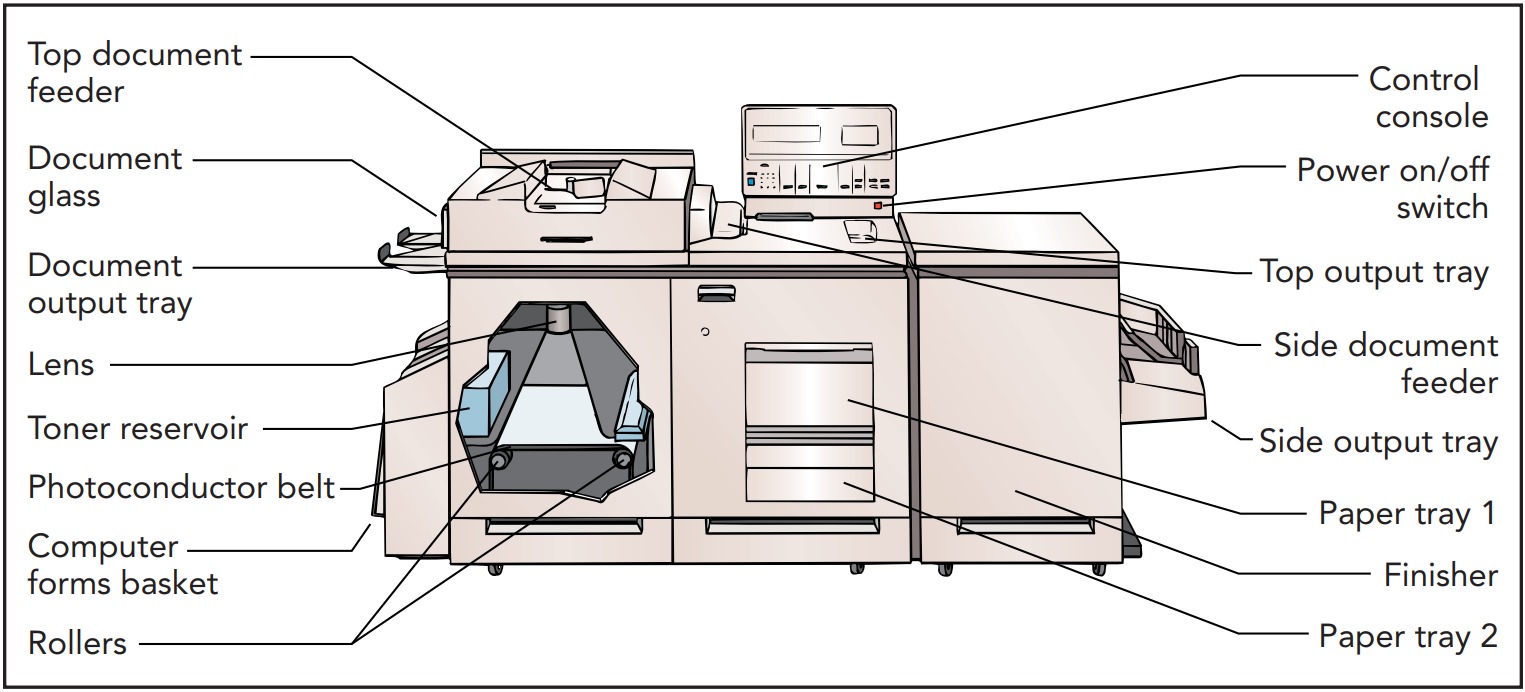

The days of carbon paper and mimeograph machines are long gone. What modern office could operate without a xerographic copier? Advertisements for copiers are everywhere, and although each manufacturer claims to make the best copiers, that's mostly just salesmanship. In reality, all xerographic copiers are based on the same principles, discovered in 1938 by Chester Carlson.

Xerography: Using Light to Print Copies

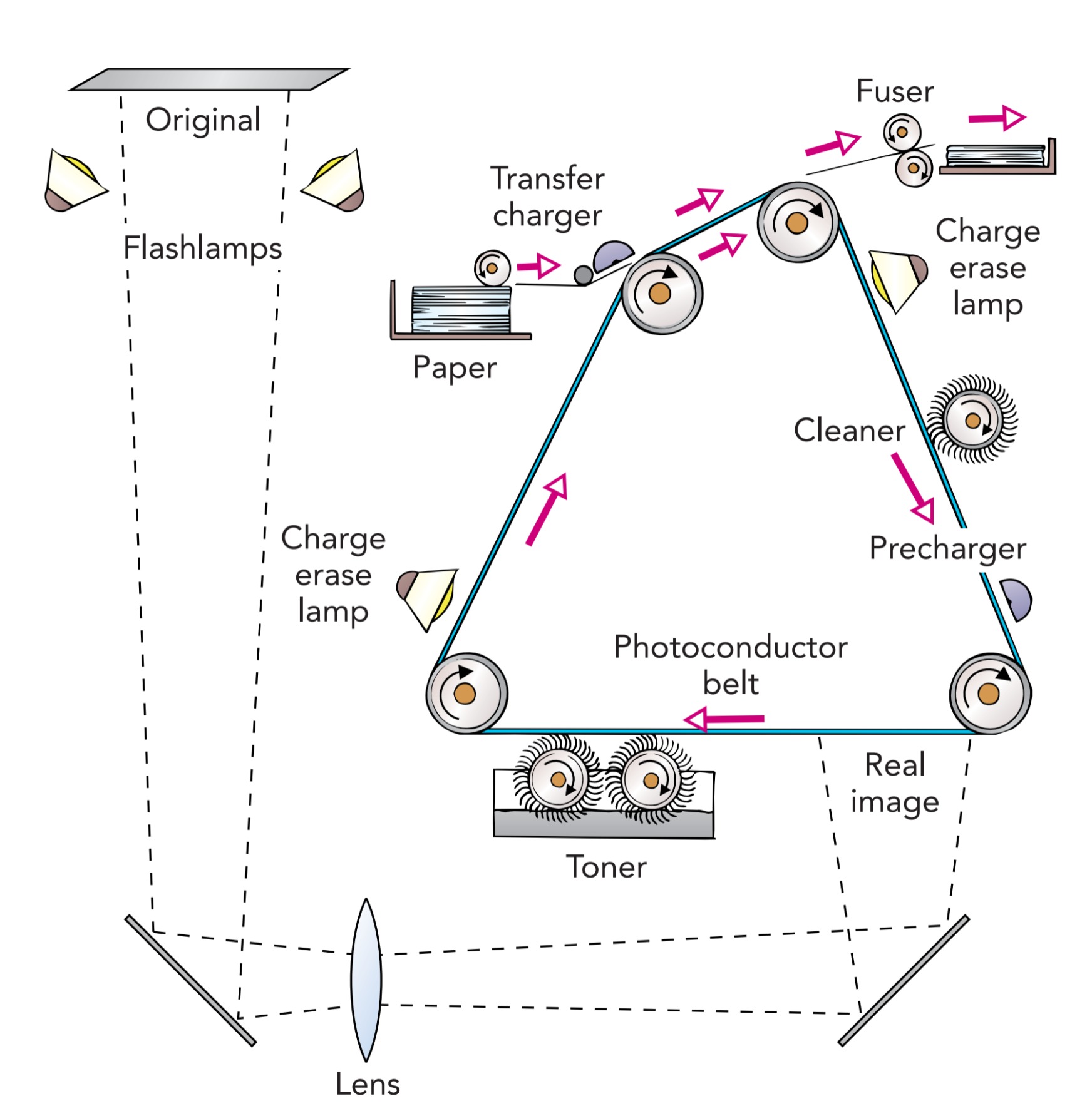

The image that a xerographic copier prints on a sheet of paper begins as a pattern of tiny black particles or toner on a smooth, light-sensitive surface. The copier uses static electricity and light reflected from the original document to arrange this toner on the surface and then carefully transfers the toner to the paper. Invented in 1938 by Chester Carlson is a process is basically related to the use of static electricity.

At the heart of the xerographic copier is a thin, light-sensitive surface made from a photoconductor, a normally insulating material that becomes a conductor while exposed to light. Although the darkened photoconductor can keep positive and negative charges apart, these charges quickly draw together when light hits the photoconductor.

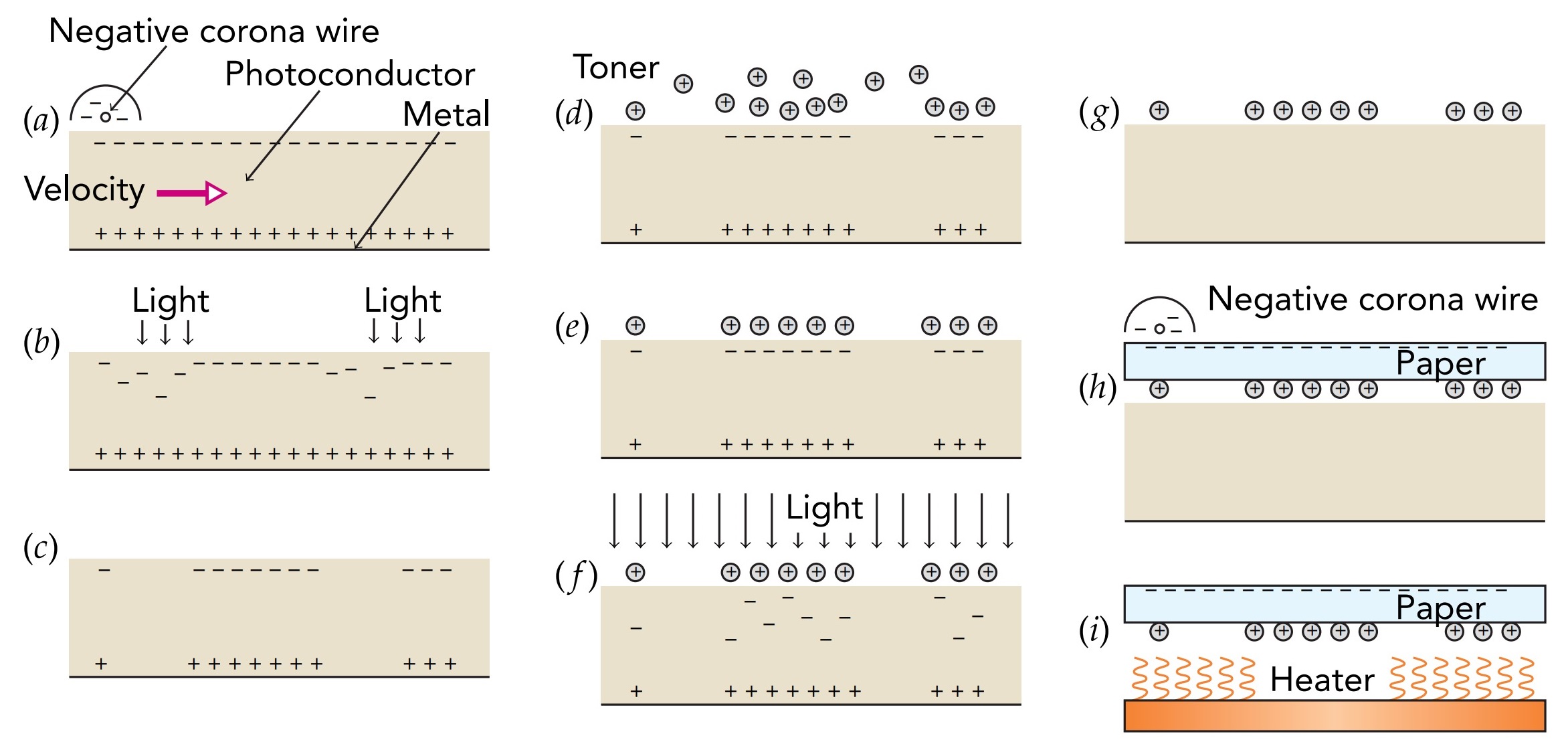

That flexibility allows light from the original document to determine the pattern of static electricity on the photoconducting surface and consequently the placement of toner on the piece of paper. Each copying cycle begins in the dark with the copier spraying negative charges onto its photoconductor. On the other side of the photoconductor is a grounded metal surface— grounded in the sense that it's electrically connected to Earth so that charges are free to flow between the two. As negative charges land on the open surface of the photoconductor, they attract positive charges onto the metal surface beneath it. When the charge-spraying process is complete, the open surface of the photoconductor is uniformly coated with negative charges while the underlying metal surface is uniformly coated with positive charge.

After this pre-charging, the copier uses a lens to cast a sharp image of the original document onto the photoconducting surface. The light hits the photoconductor only in certain places, corresponding to the white parts of the original document.

There are two standard techniques for exposing the photoconductor to light. Some copiers illuminate the whole original document with the brilliant light of a flash lamp and cast a complete image onto a flattened portion of a photoconductor belt. In other copiers, a moving lamp or mirror illuminates the original a little at a time and the image is cast as a moving stripe on a rotating photoconductor drum. Either way, charges move through any regions of the photoconductor that are exposed to light, leaving these regions electrically neutral. The result is a charge image, a pattern of electric charge on the photoconductor's surface that exactly matches the pattern of ink on the original document.

To develop this charge image into a visible one, the xerographic copier exposes the photoconductor to positively charged toner particles. This toner is a fine, insulating plastic powder containing a colored pigment, usually black. Applying toner to the photoconductor must be done gently, and it's often accomplished with the help of Teflon-coated iron balls. These tiny balls are held together in long filaments by a rotating magnetic shaft so that the shaft resembles a spinning brush with extraordinarily soft bristles. These bristles wipe toner particles out of their storage tray and onto the photoconductor. Contact with the Teflon leaves the toner particles positively charged, so they stick to the negatively charged portions of the photoconductor.

The photoconductor now carries a black image of the original document, an image that the copier must transfer to the paper. Before attempting that transfer, the copier first weakens the photoconductor's grip on the toner by exposing it to light from a charge erase lamp. This light eliminates the photoconductor's charge and leaves the positively charged toner particles clinging only loosely to its surface.

The copier then transfers the toner image to a blank sheet of paper by pressing that paper lightly against the photoconductor while spraying a negative charge onto the paper's back. The positively charged toner is attracted to the negatively charged paper, and the two leave the photoconductor together. The copier then heats and presses the copy, permanently fusing the toner onto the paper. Once the image has been transferred to the paper, the copier cleans its photoconducting surface in preparation for the next copy; a second charge erase lamp eliminates any remaining charge, and a brush or squeegee mops up any residual toner.

With that introduction to xerography, you can already explain many things about copiers. For example, while fixing a copier jam, you may find that you have removed unfinished copies—ones bearing toner images that haven't yet been fused onto the paper. The toner of an unfused copy comes off on your hand because it's held in place only by electrostatic forces. When you replace the toner cartridge in a personal copier, in addition to adding new toner, you're also installing a new precharge system, photoconductor drum, and toner applicator.

Discharges and Electric Fields

At the start of the copy cycle, the xerographic copier coats its photoconducting surface uniformly with electric charges. Because this precharging process is done in the dark, while the surface is an electrical insulator, the charges must be sprayed onto it like paint. The copier's charge sprayer is a corona discharge, a gentle sustained spark that forms in the air near a needle or fine wire that's kept at high voltage.

It's a type of discharge, a flow of electric charge through a gas. Air is normally an insulator because its atoms and molecules are neutral and can't convey charge from one place to another. However, by seeding air liberally with individual charged particles, the copier manages to turn that air into a conductor and then to produce a discharge in it.

The copier uses electrostatic forces to accelerate the initial stray charges to enormous speeds and lets them smash into air's neutral particles. When hit hard enough, a neutral air particle breaks into oppositely charged fragments and thus adds two more free charges to the air. These new charges join the mix, accelerating, colliding, and breaking up still more air particles. A cascade of collisions ensues, and the air "breaks down," transforming from an insulator to a conductor. The copier then uses this conducting air to spray the photoconductor with charges.

The electrostatic force on our charge as the result of its one interaction with something local: an electric field, an attribute of space that exerts an electrostatic force on a charge. The surrounding charges create the electric field and that electric field pushes on our charge. The electrostatic force on our charge depends on the charge's location in space and time, so the value of the electric field also depends on space and time. The electric field is a vector field; at each point, its magnitude is the amount of electrostatic force it exerts per unit of electric charge and its direction is the direction in which it pushes a positive charge. A particle carrying a negative amount of charge (an electron) experiences a force opposite the electric field. The SI unit of the electric field is the newton per coulomb (abbreviated N/C). Ordinary air breaks down in an electric field of about (3 \times 10^6) V/m, or, in customary units, about 30,000 V per centimeter. At that field, free charges accelerate so rapidly that a cascade of charge-freeing collisions suddenly transforms air from a nearly perfect insulator into a reasonably good conductor.

A corona discharge does more than just turn air into a conductor; it also produces an outward spray of electric charges. Those charges are pushed outward by the electric field surrounding the corona wire. Since the copier's corona wire has a negative volt age, the surrounding electric field points toward that wire. Because negative charges accelerate opposite an electric field, the copier's corona produces a shower of outgoing negative charges. They spray onto the photoconducting surface as it moves steadily past the corona, and the photoconductor thus acquires a uniform coating of negative charges.

As each negative charge lands, it draws a positive charge onto the grounded metal surface beneath the photoconductor and the attraction between those two opposite charges holds them firmly in place. While the photoconductor's open surface is acquiring its uniform negative charge, the metal layer underneath is acquiring an equivalent positive charge. This process, whereby a grounded conductor acquires a charge through the attraction of a nearby opposite charge, is called "charging by induction."

The induced positive charge on the metal side of the photoconductor is important to the xerographic process for several reasons. First, it lowers the electrostatic potential energy of the negative charge so that the surface's negative voltage isn't as enormous. Second, without that positive layer nearby, repulsion between like charges would tend to push negative charges on the open surface toward the edges of the photoconductor and distort the resulting images.

Most significantly, however, the positive charge layer gives the negative charge layer somewhere to go when the photoconductor is exposed to light! Wherever light from the original document turns a patch of the photoconductor into a conductor, the negative and positive charge layers rush together and cancel. The resulting uncharged portion of the photoconductor subsequently attracts no toner and produces a white patch on the finished copy.

Having come full circle, we can now see how the copier achieves its goal. It uses a corona discharge to coat a photoconducting surface with a negative charge and then selectively erases portions of that charge layer with light from the original document. The remaining charged patches on the photoconductor attract positively charged black toner, which is then transferred permanently to the paper.