Five patents have been granted in one year June 2023-July 2024

Maglve EDM has been developed, six papers have been published from 2022-2023

Mangal Singh Sisodiya, Shashank, Shukla, Vivek Bajpai, Feasibility analysis of novel Maglev EDM by comparing with conventional micro EDM , Scientific Reports, pp 1-13, vol 12, 2022, Click here

Brief IntroductionAssociate Professor in the Department of Mechanical Engineering at Indian Institute of Technology (ISM) Dhanbad, India. PhD in Mechanical Engineering from Indian Institute of Technology Bombay Mumbai India, in 2013 and M.E. degree in Production Engineering from Shri GS Institute of Technology and Science, Indore India, in 2006.

E-mail: vivek@iitism.ac.in | vbajpai007@rediffmail.com

Phone(O): +91-3262235075

Education

Ph.D. (July 2008 to Jan. 2013) Click here to see a glimpse of PhD work

Indian Institute of Technology, Bombay

MH, India

"Characterization and Modeling of Pyrolytic Carbon Micromachining for Creation of Engineered Features"

PhD Supervisor:Prof. Ramesh K Singh

M.E. in Production Engieering (July 2006 to June 2008)

Shri GS Institute of Technology and Science

Indore, Madhya Pradesh, India

First Division

ME Supervisor:Prof. Durgesh Joshi

Graduation, B.E. in Mechanical Engineering (July 2002 to Jan. 2006)

Rewa Engineering College

Rewa, Madhya Pradesh, India

First Division

Education

Ph.D. (July 2008 to Jan. 2013) Click here to see a glimpse of PhD work

Indian Institute of Technology, Bombay

MH, India

"Characterization and Modeling of Pyrolytic Carbon Micromachining for Creation of Engineered Features"

PhD Supervisor:Prof. Ramesh K SinghM.E. in Production Engieering (July 2006 to June 2008)

Shri GS Institute of Technology and Science

Indore, Madhya Pradesh, India

First Division

ME Supervisor:Prof. Durgesh JoshiGraduation, B.E. in Mechanical Engineering (July 2002 to Jan. 2006)

Rewa Engineering College

Rewa, Madhya Pradesh, India

First Division

Work Experience

Associate Professor

Department of Mechanical Engineering

IIT(ISM) DHANBAD, India

April 13, 2022 - present

Assistant Professor

Department of Mechanical Engineering

IIT(ISM) DHANBAD, India

Aug, 2015 - April 12, 2022

Assistant Professor

School of Engineering

Mahindra Ecole centrale Hyderabad, India

Aprl, 2014 - Aug, 2015

Post doctoral

Department of Mechanical Engineering

Ulsan National Institue of Technology and Science, Ulsan, South Koarea

March, 2013 - March, 2014

Work Experience

Associate Professor

Department of Mechanical Engineering

IIT(ISM) DHANBAD, India

April 13, 2022 - present

Assistant Professor

Department of Mechanical Engineering

IIT(ISM) DHANBAD, India

Aug, 2015 - April 12, 2022

Assistant Professor

School of Engineering

Mahindra Ecole centrale Hyderabad, India

Aprl, 2014 - Aug, 2015

Post doctoral

Department of Mechanical Engineering

Ulsan National Institue of Technology and Science, Ulsan, South Koarea

March, 2013 - March, 2014

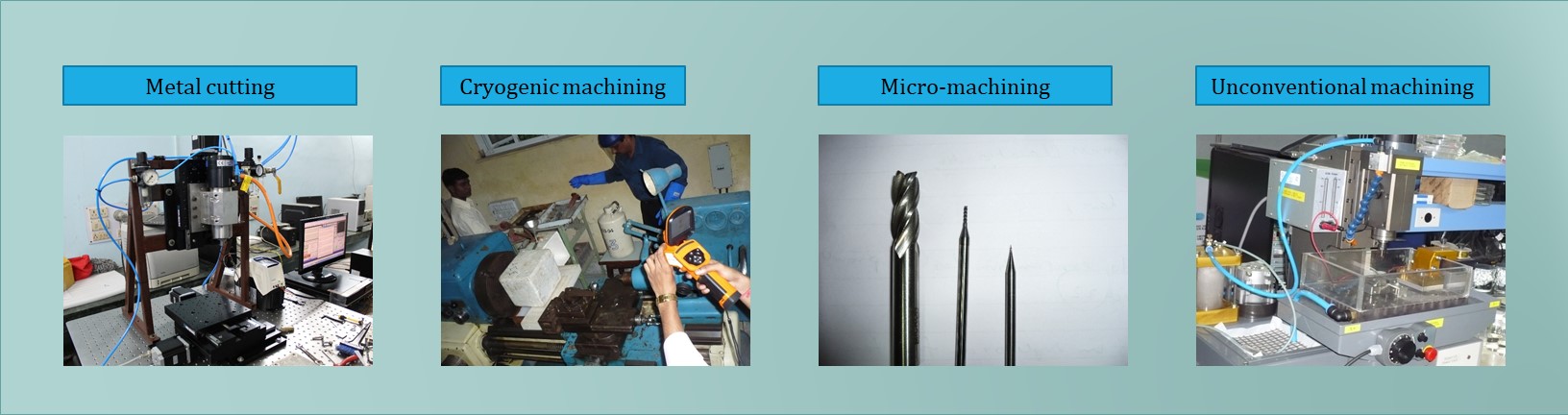

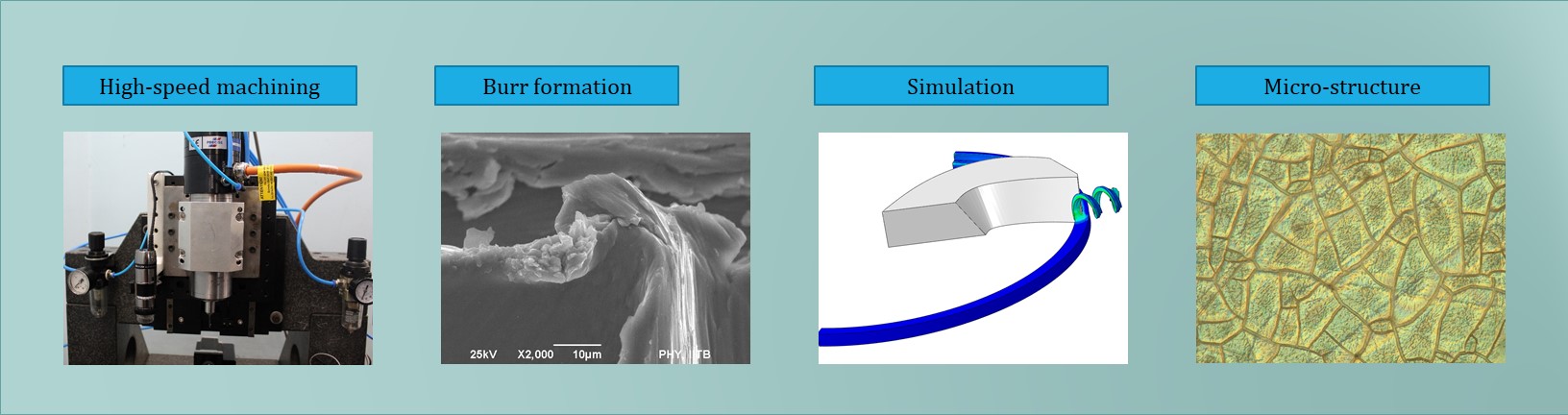

Research Interests :

Key Publications (on March 4, 2022)

Journal Publications

01. Jain, A., Kumari, N., Jagadevan, S. et al. Surface Free Energy and Bacterial Attachment on Microtextured Ti6Al4V Alloy, J. of Materi Eng and Perform, 30, 3968–3975 (2021). Click here

02. Jain, A., Kumari, N., Jagadevan, S. et al. Surface properties and bacterial behavior of micro conical dimple textured Ti6Al4V surface through micro-milling, Surfaces and Interfaces,, 21, 100714 (2020). Click here

03. Jain, A., Bajpai V, Chapter 1 - Introduction to high-speed machining (HSM), High Speed Machining, Academic Press,, 1-25 (2020). Click here

04. Jain, A., Bajpai V, Mechanical micro-texturing and characterization on Ti6Al4V for the improvement of surface properties, Surface and Coatings Technology, 380, 125087 (2019). Click here

05. Jain, A. , Kumar, S., Bajpai, V. et al., Replacement of Hazard Lubricants by Green Coolant in Machining of Ti6Al4V: A 3D FEM Approach, Int. J. Precis. Eng. Manuf., 20, 1027–1035 (2019). Click here

06. Jain, A. , Khanna, N, Bajpai V, FE simulation of machining of Ti-54M titanium alloy for industry relevant outcomes Measurement, 129, 268-276 (2018). Click here

07. Mangal Singh Sisodiya, Shashank, Shukla , Vivek Bajpai, Feasibility analysis of novel Maglev EDM by comparing with conventional micro EDM , Scientific Reports, pp 1-13, vol 12, 2022, Click here

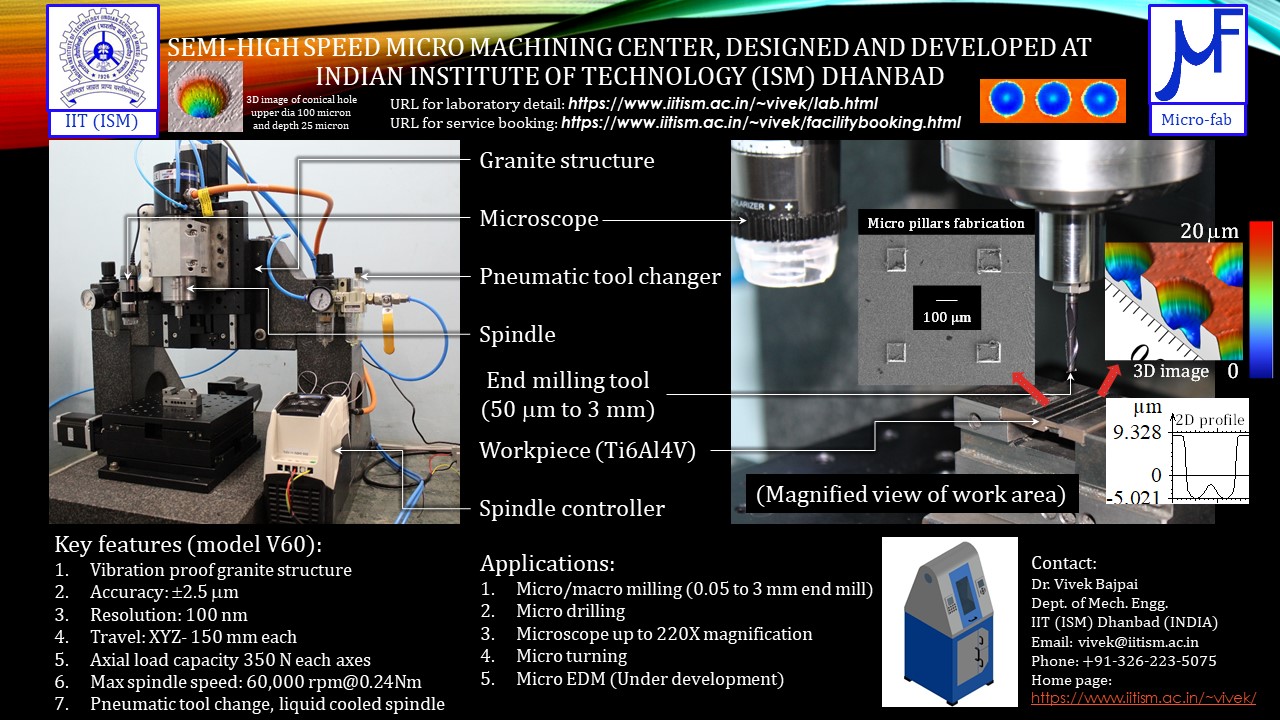

08. Arnab Das, Shashank, Shukla , Mohan Kumar, Chitransh Singh, Madan Lal Chandravanshi, Vivek Bajpai, Development of a vibration free machine structure for high-speed micro-milling center , The International Journal of Advanced Manufacturing Technology, pp 3489-3506, vol 116, 2021, Click here

09. Shashank, Shukla , Vivek Bajpai, Effect of cryogenic quenching on microstructure and microhardness of Ti-6Al-4V alloy , Materials Letters, 267,127532, 2020, Click here

Patent Publications01. Vivek Bajpai, Rachit ranjan, Shashank, Shukla , A magnet driven servo mechanism for macro/micro electrical discharge machining (EDM) , Indian Patent,Application no 202031054445 A, The Patent Office Journal No. 06/2021 Dated 05/02/2021,pp 5376 Click here

02. Vivek Bajpai, Arnab Das, Shashank, Shukla , Chitransh Singh, Mohan Kumar, Madan Lal Chandravanshi, A machine structure to reduce vibration of micro-milling machine , Indian Patent,Application no 201931049978 A, The Patent Office Journal No. 30/2020 Dated 24/07/2020,pp 27773 Click here

orcid.org/0000-0003-4811-6611

orcid.org/0000-0003-4811-6611