Brief Introduction to the Laboratory

Micro fabrication is the primary objective of the lab. In addition, micro machining: Simulation and experimental characterization of hard and difficult to cut metals are the common jobs. The lab is situated at the central workshop of Indian Institute of Technology (ISM) Dhanbad, India (formerly Indian School of Mines Dhanbad). At present the lab has 10 members including students (PhD and MTech)

Research areas in the laboratory

Facilities

Click for booking a facility

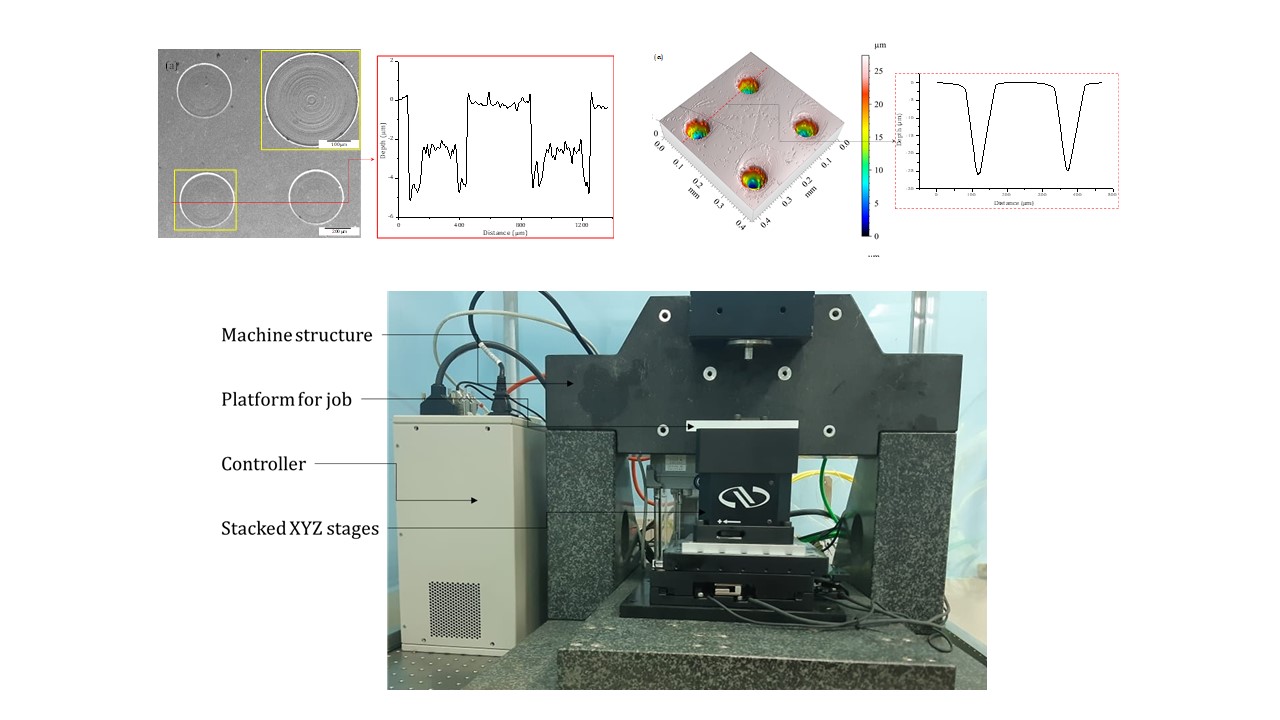

1. Cryogenic-High speed micro machining center

Finanical support: FRS Grant of IIT (ISM) Dhanbad

Accuracy 2.5 microns, spindle speed 60000 rpm

Other features: Cryogenic cooling

In built microscope (200X)

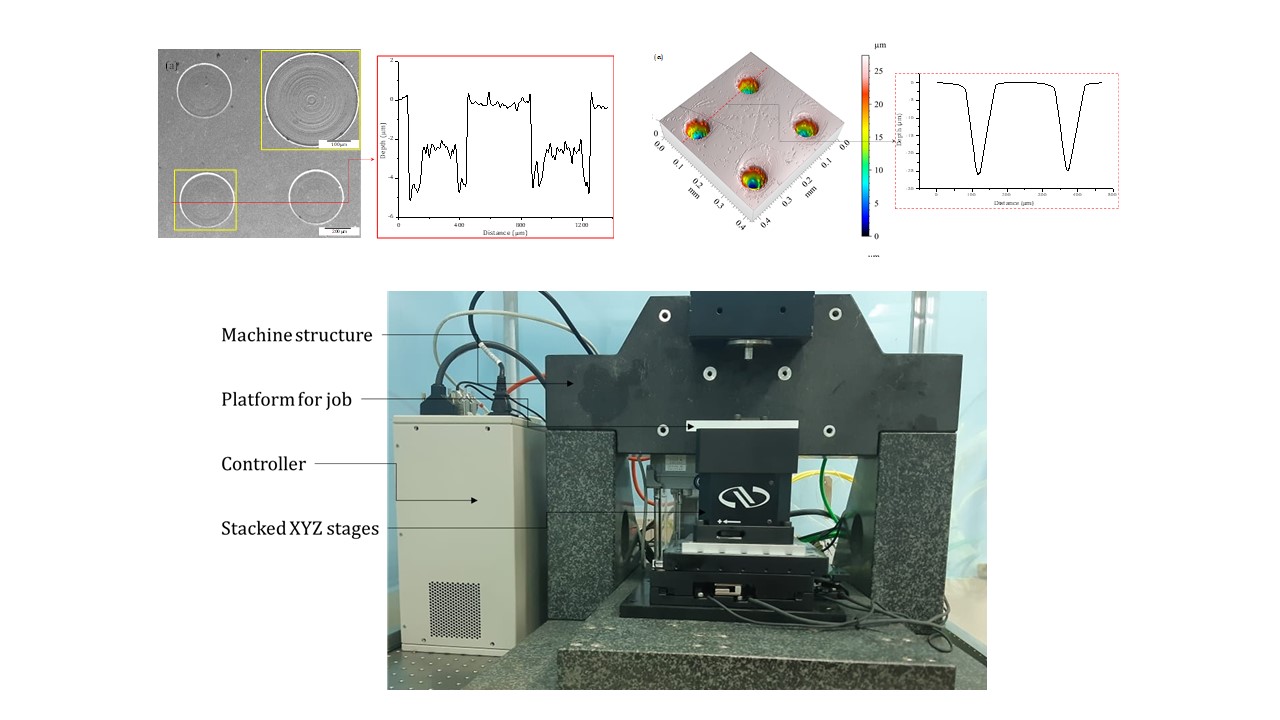

Application: 3D free form features of micro size

Cryogenic machining video Click to download

2. Ultra precision High speed micro machining center

Finanical support: DST (ECR), Grant number: ECR/2016/001956

Accuracy 500 nm, spindle speed 140000 rpm

Other features: Cryogenic/MQL cooling

Application: 3D free form features of micro size

Upcoming Facilities

1. Dynamometer

Financial Support: FIST (DST)

High sampling rate

High sensitivity

Micro forces can be measured

Application: Force sensor in milling/drilling (4 axes)

2. Profilometer

Financial Support: FIST (DST)

Nano-level surface roughness

Step height

Micro level 3D scan

Application: 3D profile and surface roughness

Facilities

Click for booking a facility

1. Cryogenic-High speed micro machining center

Finanical support: FRS Grant of IIT (ISM) Dhanbad

Accuracy 2.5 microns, spindle speed 60000 rpm

Other features: Cryogenic cooling

In built microscope (200X)

Application: 3D free form features of micro size

Cryogenic machining video Click to download

2. Ultra precision High speed micro machining center

Finanical support: DST (ECR), Grant number: ECR/2016/001956

Accuracy 500 nm, spindle speed 140000 rpm

Other features: Cryogenic/MQL cooling

Application: 3D free form features of micro size